Wastewater treatment and Recycling plant Design Products

Designing products for wastewater treatment and recycling plants involves creating systems and equipment that effectively remove contaminants from wastewater and facilitate its reuse or safe disposal.

Here are some common products and components used in these plants:

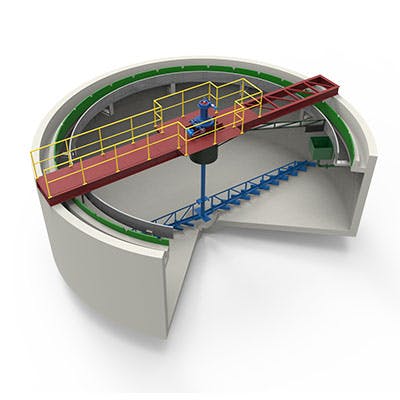

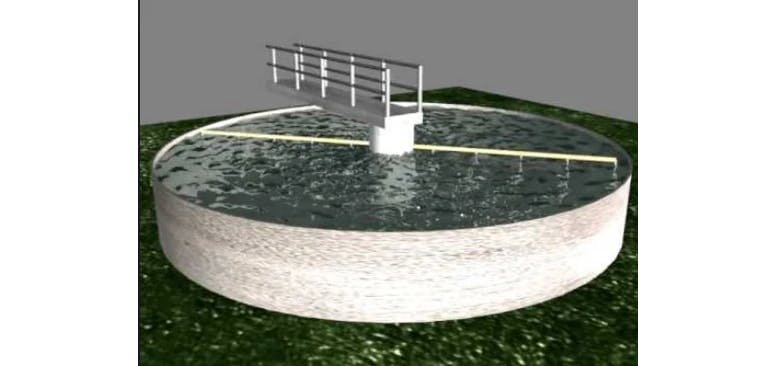

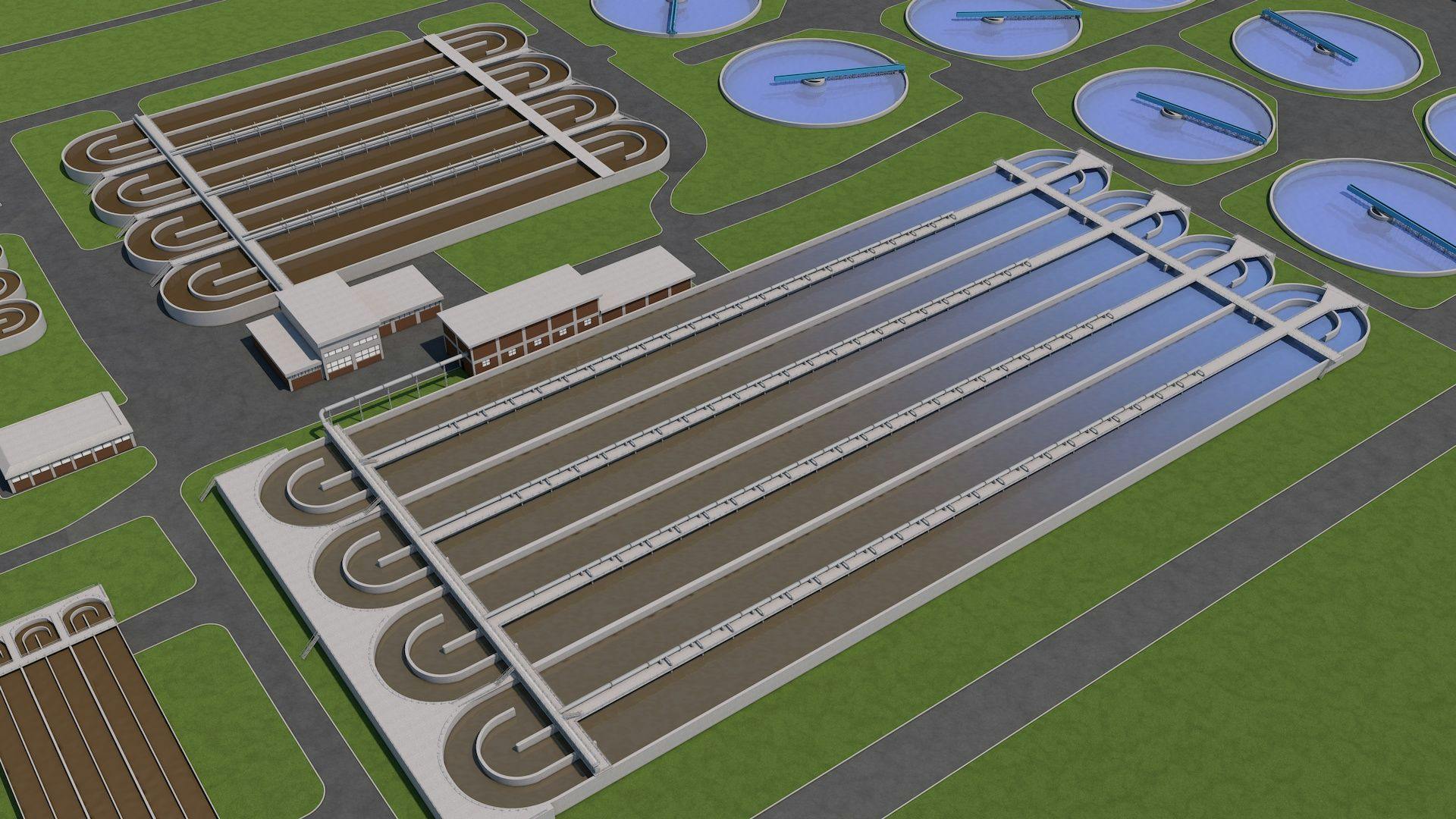

1. Clarifiers: These are large tanks used to separate solids from liquids in wastewater through sedimentation. They can be circular or rectangular in shape.

2. Filter press : Various types of filters are used to remove suspended solids, organic matter, and other contaminants from wastewater. Examples include sand filters, activated carbon filters, and membrane filters.

3. Aeration Systems: Aeration systems introduce air into the wastewater to stimulate the growth of aerobic bacteria, which break down organic pollutants. Different methods include diffused aeration, mechanical aeration, and surface aeration.

4. Biological Treatment Systems: These systems utilize microorganisms to degrade organic pollutants in wastewater. Examples include activated sludge systems, sequencing batch reactors (SBRs), and trickling filters.

5. Chemical Treatment Systems: Chemicals such as coagulants, flocculants, and disinfectants are used to remove contaminants from wastewater. Products include dosing systems, mixing tanks, and chemical feed pumps.

6. UV Disinfection Systems: Ultraviolet (UV) light is used to disinfect wastewater by inactivating pathogens such as bacteria and viruses. UV disinfection systems typically include UV lamps, reactors, and control systems.

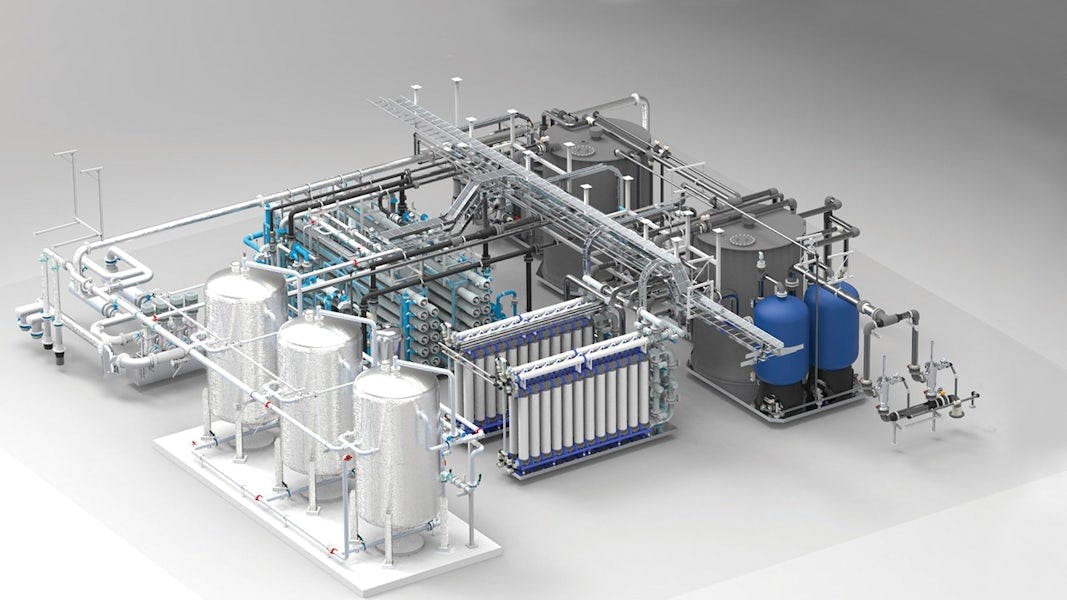

7. Membrane Bioreactors (MBRs): MBRs combine biological treatment with membrane filtration to produce high-quality effluent. Components include membrane modules, aeration systems, and solids separation units.

8. Sludge Treatment Equipment: Sludge generated during wastewater treatment must be treated before disposal or reuse. Products include sludge dewatering equipment (e.g., belt presses, centrifuges), sludge drying beds, and incinerators.

9. Monitoring and Control Systems: These systems monitor various parameters such as pH, dissolved oxygen, and turbidity in the wastewater treatment process. They include sensors, data loggers, and control panels.

10. Piping and Valves: Pipes, valves, and fittings are essential for transporting wastewater and chemicals throughout the treatment plant. Materials used include PVC, HDPE, stainless steel, and ductile iron.

11. Recycling Systems: These systems treat wastewater to a quality suitable for reuse in non-potable applications such as irrigation, industrial processes, and toilet flushing. Components may include advanced filtration, disinfection, and storage tanks.

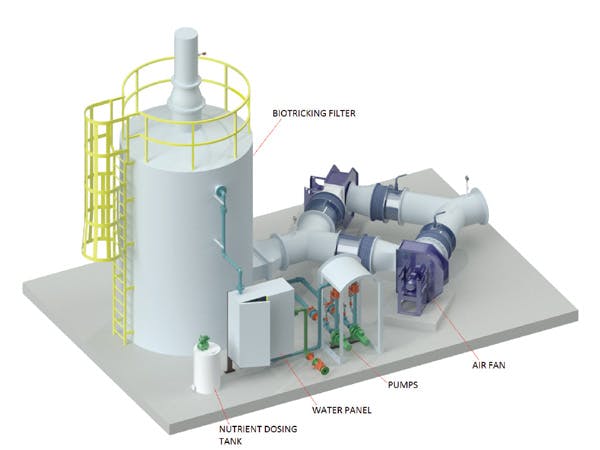

12. Odor Control Systems: To mitigate odors generated during wastewater treatment, odor control systems such as biofilters, activated carbon filters, and chemical scrubbers are used.

Designing these products requires a deep understanding of wastewater treatment processes, regulations, and environmental considerations. Additionally, factors such as plant size, capacity, and budget must be taken into account to ensure effective and efficient operation.